TEAM

Dr. Ayşe Çağıl Kandemir (Head)

Former Students

- Fatma Dönmez

- Arda Baytaroğlu

- Mert Utku

- Fatih İbrahimoğlu

Collaborators:

Prof. Dr. Hatice Can Kaplan

Dr. Şehram Dizeci

Dr. Ömer Music

Dr. Ayşe Çağıl Kandemir

Dr. Ayşe Çağıl Kandemir received her bachelor's (2004-2008) and master's degrees (2008-2011) from METU Metallurgical and Materials Engineering Department. She completed her doctoral studies in the Materials Science Department of ETH Zürich between 2011-2016. She started her academic career as a research assistant in the same department. She worked as a research assistant at ETH Zürich for four years. Her research interests include composite and nanocomposite materials, bioinspired materials, surface science/thin films, and atomic force microscopy/lithography. Since June 2018, she has been a TEDU Mechanical Engineering Department faculty member.

Research interests:

• Mechanical properties in reduced dimensions

• Polymers and Polymer Composites/ Nanocomposites

• Bioinspired Materials

• Surface science

• Atomic Force Microscopy

• Dip Pen Nanolithography

Education Information:

• Doctorate, ETH Zurich, Switzerland,

• Postgraduate, Middle East Technical University, Turkey,

• Undergraduate, Middle East Technical University, Turkey,

Goals:

Our laboratory specializes in the production of bio-inspired composite materials at various length scales, with the aim of achieving properties that are mutually exclusive in traditional materials, such as toughness and strength. By mimicking the structure and design of natural materials, we can create composites that exhibit superior mechanical performance.

The use of a multiscale approach is a key feature of our laboratory's methodology. We are able to produce composite materials ranging from the nanoscale to the microscale and the macroscale, allowing us to incorporate multiple levels of structural hierarchy. This enables us to mimic the complex, hierarchical structures found in natural materials, such as bone and wood, which exhibit exceptional mechanical properties.

Methods:

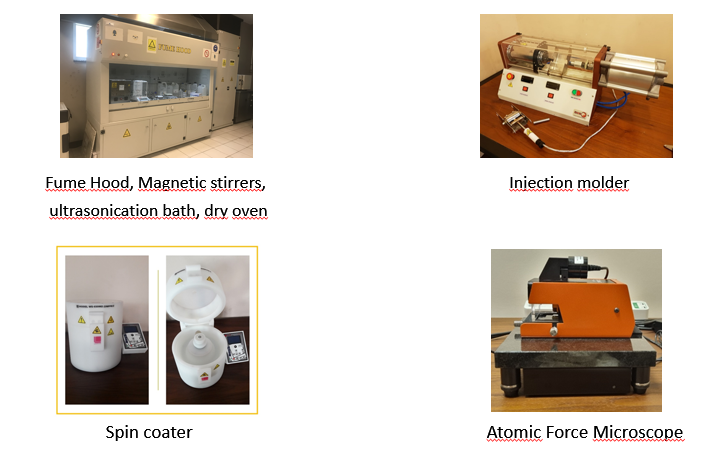

Our laboratory employs various techniques to create multi-scaled composites, including bulk manufacturing, layer-by-layer assembly via spin coating, and Atomic Force Lithography (Dip Pen Nanolithography). These techniques allow us to control the structure and properties of the materials at the nano-, micro-, and macroscales. By manipulating the composition and structure of the materials at each length scale, we can tailor their mechanical properties to meet specific engineering requirements.

Our laboratory's focus on bio-inspired composites and multi-scaled production techniques represents a promising avenue for the development of new materials with enhanced mechanical properties. By mimicking the natural world, we can achieve a level of mechanical performance that is difficult to attain through traditional approaches.

Composite production:

Equipment

Fume hood

Ultrasonication bath

Ultrasonication stirrer

Magnetic stirrers

Dry oven

Vacuum oven

Injection molder

Spin Coater

Atomic Force Microscope

Research outcomes of the laboratory could be seen in the following link: